US Dollar Exchange Rates of

25th

Oct

2023

China Yuan 7.30

Report from China

Investment

in real estate

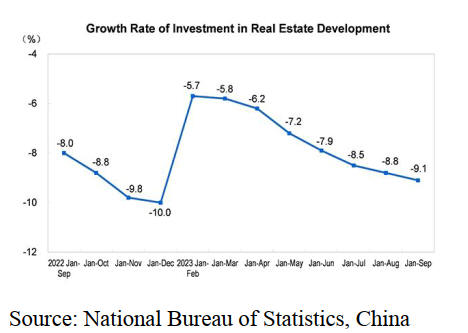

Between January and September investment in real estate

development was 8,726.9 billion yuan, a year-on-year

decrease of 9%. Investment in residential buildings was

6,627.9 billion yuan, down by 8.4%.

In the first nine months of 2023 the floor space under

construction was 8,156.88 million square metres, a year-

on-year decrease of 7% and the under construction floor

space of residential buildings was 5,742.50 million square

meters, down by 7.4%.

Retail sales in September 2023

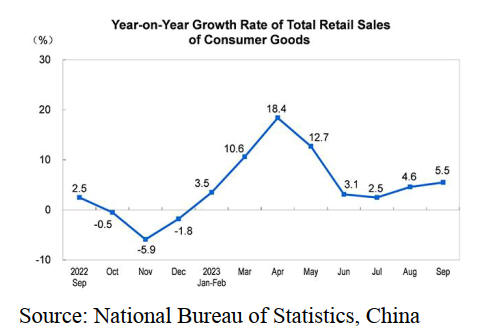

In September this year retail sales of consumer goods

reached 3,982.6 billion yuan, a year-on-year increase of

5.5% and retail sales, other than automobiles, reached

3,544.3 billion yuan, up by 5.9%. Sales of furniture rose

0.5% in September and rose by 3% in the first nine months

of this year. However, sales of Building and Decoration

materials dropped 8% in September and arealso down 8%

for the year to September.

From January to September retail sales of consumer goods

in urban areas increased almost 7% year on year as did

sales in rural areas.

Formaldehyde-free wood-based panel market share

The output of China's wood-based panesl in 2021wase

336.73 million cubic metres, a year on year increase of 8%

and came after four consecutive years of growth.With the

improvement of people's living standards in China the

safety of the living room environment became a topic of

concern and demand for formaldehyde-free wood-based

panel products increased.

The formaldehyde-free wood-based panel industry

With the green upgrading of the wood-based panel

industry the production of formaldehyde-free wood-based

panel products has steadily increased and the market share

of these products continues to expand.

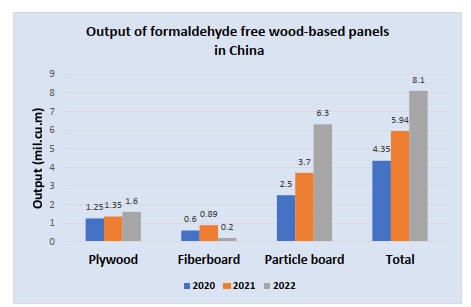

The output of formaldehyde-free wood-based panel

products was about 8.1 million cubic metres in 2022.

Formaldehyde-free plywood, fiberboard and particle board

was 1.6 million cubic metres, 0.2 million cubic metres and

6.3 million cubic metres respectively, a year on year

increase of 36%.

The output of formaldehyde-free plywood products in

China has maintained a steady growth trend in recent

years, a year on year increase of 37% in 2021 and 36% in

2022. The proportion of formaldehyde-free particleboard

is largest at 57% in 2020, 62% in 2021 and 78% in 2022.

The varieties of formaldehyde-free products have

expanded and the main adhesives include aqueous

polyurethane adhesives (EPI), bean-based protein

adhesives, lignin adhesives and thermoplastic resin film

adhesives, etc.

Formaldehyde-free plywood is mainly madewith

polyurethane, bean-based protein, thermoplastic film

adhesives in China. The proportion of formaldehyde-free

plywood made with bean-based protein adhesives

dominated and was 64% (800,000 cubic metres) in 2020,

57% in 2021 (770,000 cubic metres) and 63% (1 million

cubic metres) in 2022.

Formaldehyde-free fiberboard is mainly made with

polyurethane and bean-based protein in China. The

proportion of formaldehyde-free fiberboard made by

polyurethane adhesives dominated and is 83% (500,000

cubic metres) in 2020, 87% in 2021 (770,000 cubic

metres) and 50% (100,000 cubic metres) in 2022.

Formaldehyde-free particle board is mainly made by

polyurethane (MDI), polyurethane (EPI) and bean-based

protein adhesives in China. The proportion of

formaldehyde-free particle board made by polyurethane

(MDI) adhesives dominated and is 80% (2 million cubic

metres) in 2020, 83% in 2021 (3.08 million cubic metres)

and 90% (5.65 million cubic metres) in 2022.

Current formaldehyde emission limits for wood-based

panels

Formaldehyde release is an important indicator to evaluate

environmental performance of wood-based panels

products. There are 7 formaldehyde emission limits for

wood-based panel products in China, including 4 national

standards, 1 environmental protection industry standard

and 2 group standards.

Technical indicators of current formaldehyde emission

limits of wood-based panel have reached international

standards, of which the ENF level (0.025mg /m³) in GB/T

39600-2021 ‘The classification of Formaldehyde

emission for wood-based panels products’ is the most

stringent international requirements for formaldehyde

emission limits of wood-based panels products. ENF

levels are commonly known as formaldehyde-free levesl

in the industry. It mainly provides the formaldehyde limit

index that consumers are most concerned about.

Group standard T/CNFPIA 3002-2018 "Formaldehyde-

free wood-based panels products" gives the definition of

formaldehyde-free wood-based panels and gives the

requirements from the use of adhesive, formaldehyde

release limit (0.03 mg/m³) and TVOC release rate not

exceeding 0.50 mg/ (m2·h) (72 h).

The soluble heavy metal content of formaldehyde-free

wood-based panel products with color paint finish should

also meet the requirements of GB 18584-2001 ‘Interior

decoration materials harmful substances limits in wood

furniture’.

Non-formaldehyde and low-formaldehyde products are the

future development direction and the research on the

revision of China's formaldehyde-free wood-based panel

industry standards continues to promote the green

development of wood-based panel products industry.

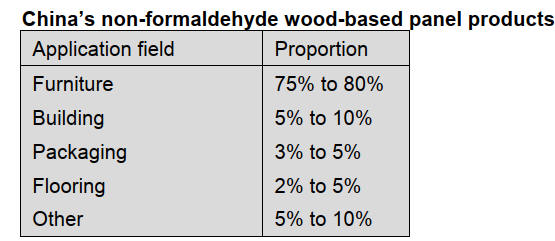

Application of non-formaldehyde wood-base panel

products

More than 95% of formaldehyde-free wood-based panels

products have surface finishes. The main finishing

methods include impregnated film paper finishing, high-

pressure laminates (HPL), polypropylene (PP) finishing,

paint finishing, polyvinyl chloride (PVC) film finishing

and continuous pressure laminate (CPL) finishing.

For the limits of indoor use for wood-based panels, GB

39598-2021’The Guidelines for indoor load limits of

wood-based panels on limiting formaldehyde release’

provides the calculation method for indoor load limits of

wood-based panels on the limit amount of formaldehyde

release and other information to be considered.

It is suitable for wood-based panels used in wood products

such as interior furniture, cabinets, wooden doors, wooden

wallboards and wooden floors. Depending on use

consumers can choose between E1, E0 and ENF grade or

formaldehyde-free wood-based panels products.

ENF grade and formaldehyde-free wood-based panel

products are more suitable for use in a space where the

amount of wood-based panel products is large, the space

used by sensitive people, special places such as hospitals,

nursing homes and kindergartens and special consumer

groups.

Future development prospect

The proportion of formaldehyde-free wood-based panel

products will continue to expand and the substances that

affect human health such as VOC release and free phenol

in the production process and use will gradually attract

consumer attention.

The variety of formaldehyde-free wood-based panel

products will be further enriched and the production

efficiency and quality requirements will be further

improved.

The functional requirements of formaldehyde-free and

wood-based panel products will gradually be combined

and functional formaldehyde-free products, such as ultra-

thin, shaped, flame retardant, moisture-proof, antibacterial,

insect-proof, anti-static and low-odor products, will

become one of the main development directions according

to different application fields and places. The development

of formaldehyde-free finishing materials will become

more urgent.

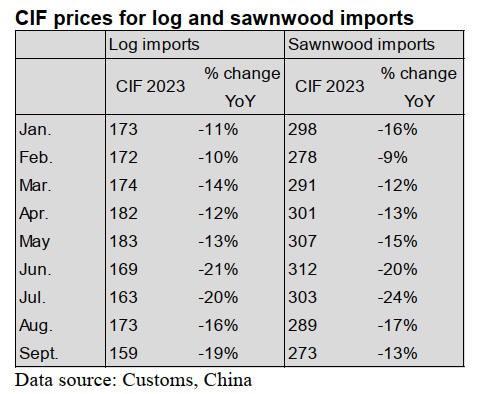

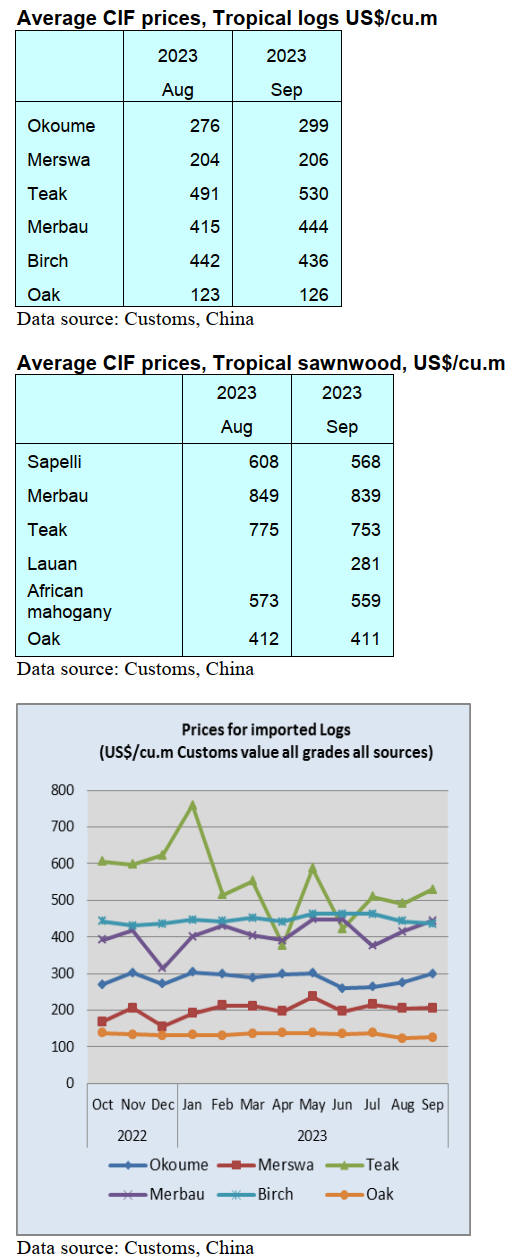

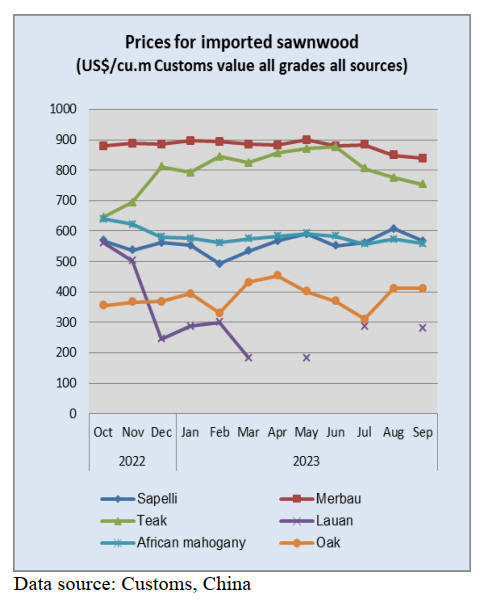

Decline in imported log and sawnwood CIF prices

According to China Customs, between January and

September 2023 CIF prices for logs and sawnwood

imports declined year on year.

The decline in CIF prices for both logs and sawnwood

imports was because global ocean freight rates have fallen

sharply and because stocks at Chinese ports iare high due

to weak demand.

Largest Russian timber company shipping plywood to

China

It has been reported that the company Sveza Uralsky

(formerly Perm Plywood Factory) the largest plywood

manufacturer in Russia’s Perm Krai Region has started

shipping plywood to China. Sveza Uralsky lost its markets

in Europe in 2022 due to Western sanctions and company

revenues fell dramatically and the company posted net

losses for several years. The company has diversified with

new markets such as East Asia, CIS countries, the Middle

East and Africa.

According to the Russian Animal and Plant Inspection and

Quarantine Bureau the export of birch plywood from Perm

Krai to China increased to 8,800 cubic metres between

January and August.

See:http://www.rc-sc.cn/newsshow.aspx?mid=380&id=8820

GTI-China index for September

In September the GTI-China index registered 37.3%, a

decrease of 15.3 percentage points compared to that of the

previous month, falling below the critical value (50%)

after 2 months and indicating that the business prosperity

of the timber enterprises represented in the GTI-China

index shrank from August.

The production index registered 34%, a decrease of 22

percentage points from the previous month and fell below

the critical value after 2 months indicating that the

production volume of the timber enterprises represented in

the GTI-China was less than that of August.

The new orders index registered 40%, a decrease of 13

percentage points from the previous month and fell below

the critical value after 2 months indicating that the number

of new orders of the timber enterprises represented in the

GTI-China was less than that of August.

The export orders index registered 50%, an increase of 8

percentage points from the previous month and rose after 5

months indicating that the number of export orders of the

timber enterprises represented in the GTI-China was the

same with that of August.

On 15 September the National Bureau of Statistics

released macroeconomic data for August. In terms of trade

China's exports in August were down 3.2% and imports

were down 1.6%. In the industrial sector profits of

industrial enterprises grew by 17% year-on-year and

achieved positive growth for the first time since the second

half of last year.

The General Office of the Central Committee and the

General Office of the State Council jointly issued a "Plan

on Deepening the Reform of the Collective Forest Right

System" which outlines multiple tasks for instance to

support eligible forestry carbon sink projects.

See:https://www.itto-ggsc.org/static/upload/file/20231017/1697507334917952.pdf

|