US Dollar Exchange Rates of

25th

May

2022

China Yuan 6.6928

Report from China

Housing sector slump continues

A press release from the National Bureau of Statistics

provides data on housing sector developments between

January and April this year.

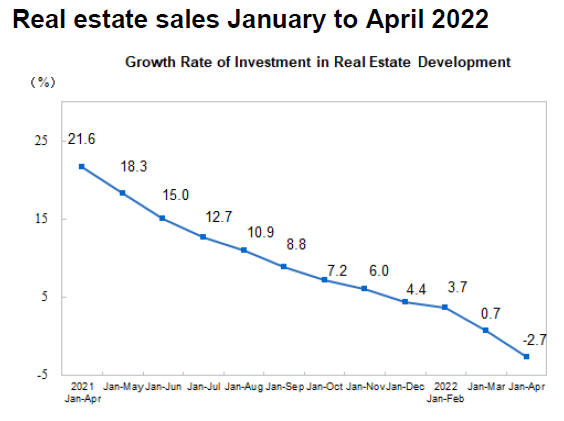

Total investment in real estate development in the four

months to April 2022 declined 2.7% year on year while

residential investment dropped 2.1%. The construction

area of new homes was down 26% and the area of

completed housing was down 11.9%.

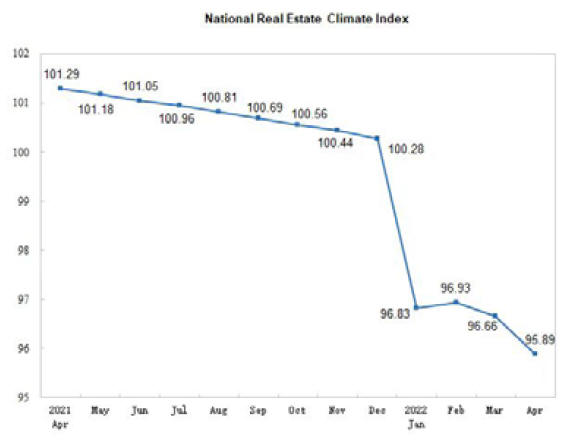

National Real Estate Climate Index

In April this year the real estate development climate

index was 96 and has been falling since December 2021.

See:

http://www.stats.gov.cn/english/PressRelease/202205/t20220517_1857527.html

Assistance for real estate developers

China's financial regulators have instructed the country's

state-owned asset management companies and local banks

to extend assistance to real estate developers that are in

financial trouble.

The sectors liquidity situation has deteriorated with many

companies struggling to refinance debt and pay creditors

as home sales fall and investment slows. Efforts to

stabilise the crisis-hit sector are critical as this sector

accounts for around a quarter of GDP and consumption of

wood products in housing is at the core of the

development of the timber industries.

In the past two months the government has introduced a

variety of measures to restore stability in a sector hit by

defaults on offshore debt obligations, credit rating

downgrades and share sales.

A surge of covid infections began in April which disrupted

trade and production. Although there was a slight recovery

in May demand for wood products for construction

remains weak. A notice was recently released jointly by

the People's Bank of China and China Banking Insurance

Regulatory Commission outlining plans for assistance.

It has been stated that the covid epidemic is under control

in Shanghai and production is expanding. The pace of

resumption in more than a dozen regions in China has

reportedly reached 70-90%.

See:

http://www.cbirc.gov.cn/cn/view/pages/ItemDetail.html?docId=1051459&itemId=915

and

https://asia.nikkei.com/Spotlight/Caixin/Chinese-banks-and-baddebt-managers-urged-to-rescue-real-estate

Debut of faced plywood from automatic production

line

The first production of faced plywood has rolled off and

automatic continuous production line marking a success

for plywood mills in Linyi City, Shandong Province. This

paves the way for the transformation of the Linyi wood

industry in production of high-quality products to

international standards.

As the largest plywood production and export base Linyi

City has more than 3,300 plywood production enterprises

with an annual output of 36 million cubic metres,

accounting for 60% of the provincial total.

At present, the "automatic continuous production line of

one-step faced plywood" has successfully completed the

batch trial production and can be formally put into

operation in May 2022.

It is reported that one production line can produce 20,000

standard plywood panels per day (equivalent to the

capacity of 20 traditional enterprises).

The number of workers has been reduced from 1,500 to 70

and the mill area has been reduced from more than 13

hectares to 7 hectares. The new mill can produce 300,000

cubic metres of faced plywood annually.

Overstocking at Taicang Port

At present, the covid control measures in Taicang City

remain strict and timber transport is limited which has

created storage headache for Taicang Port. It is reported

that timber stocks have risen to about 1.7 million cubic

metres, a record high. Shanghai and Taicang areas of the

Yangtze River Delta have been heavily affected by the

current covid outbreak and are still not fully open.

As of mid May around 8,000 containers have been moved

out from the port but more than 1,000 containers of North

American timber are still stranded. It has been reported

that timber is not allowed to be unloaded at Taicang Port

and is being directed to other regional ports such as

Qingdao and then barged back along the Yangtze River.

¡®Intelligent¡¯ production of bamboo particleboard

It has been reported that a company in the Daling

industrial zone, Shaoguan City has produced 200,000

cubic metres of bamboo particleboard using an

¡®intelligent¡¯production line.

It is estimated that the annual utilisation of bamboo and

bamboo residues will reach 260,000 tonnes creating an

output value of more than RMB300 million and expanding

employment.

Sterilising wood panels the "new vogue"

Consumers have high expectations for safe products used

in the home and are no longer satisfied only with the

concept of environment-friendly and no formaldehyde.

The current trend is to antibacterial and sterilised products,

the new standard for the wood panel in the industry.

Products now marketed have antibacterial and mold

treatment such as the photocatalyst antibacterial ecological

panel, natural bean fragrance antibacterial ecological panel

and zinc antibacterial panel. Some enterprises add chitin,

nano-silicon titanium self-cleaning agent and zinc and

other active ingredients on the decorative surface of wood

panel to form a protective cover claiming this blocks

bacteria.

Household consumption has quietly changed during the

epidemic. The preference for antibacterial products has

also prompted manufacturers to step up research and

development, even though the market share for

antibacterial products in China remains small.

For home building materials enterprises such a trend

means new business opportunities.

|