|

Report from

Europe

UK tropical wood imports slowdown

The rebound in UK imports of tropical wood products as

the first wave of the pandemic receded in summer last year

slowed in the last quarter of 2020 as the country, like

much of the rest of the Europe, reimposed lockdown

measures in response to the second larger wave which hit

at the start of the winter months.

In addition to a slowdown in overall UK business activity

at the end of 2020, there are also reports of severe supply

problems in the UK building sector, including for products

imported from South East Asia and China, due to limited

container space and rising freight costs.

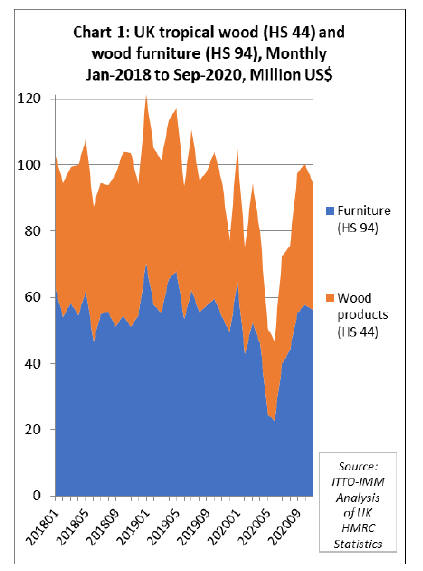

Total value of UK imports of tropical wood and wood

furniture months increased only slightly from US$98

million in October to US$100 million in November, but

then receded again to US$95 million in November (Chart

1 above).

Total UK tropical wood and wood furniture imports in the

11 months to November 2020 were US$892 million, 23%

less than the same period in 2019.

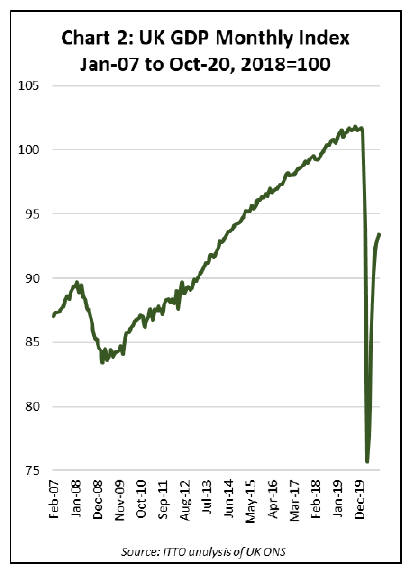

When the recovery in the UK economy began to slow in

the last quarter of 2020, GDP in October 2020 was still

8% percentage points down compared to February 2020

just prior to the pandemic (Chart 2).

The IMF now estimates that UK GDP contracted 10% for

the year in 2020, the biggest fall of any G7 country, and

forecasts that GDP will expand by 4.5% this year, down

1.4% points from the IMF¡¯s previous 5.9% growth

forecast published in October.

According to IMF, the recent acceleration of the UK¡¯s

vaccination programme is not expected to give an extra

boost to UK growth until 2022 when the forecast growth

rate has been upgraded by 1.8 percentage points to 5%.

This aligns closely with the latest forecast by UK

Treasury¡¯s independent spending watchdog, the Office for

Budget Responsibility (OBR), which also indicates that

the UK economy will not return to its pre-crisis level until

the end of 2022, at the earliest.

Strong demand but freight problems lead to shortages

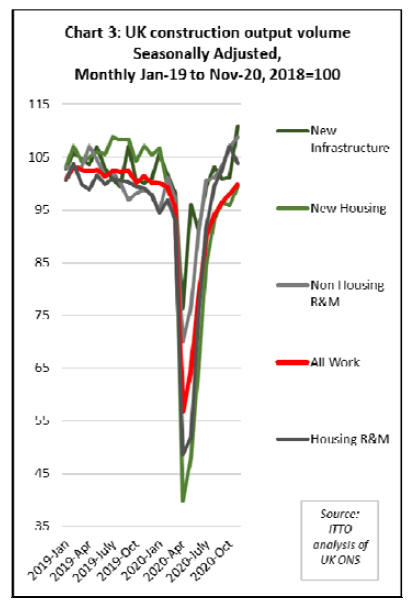

A positive factor for the UK timber trade in 2020 was that

the initial downturn in construction sector activity, which

is a key driver of timber demand, during the first ¡°great

lockdown¡± was short and followed by a stronger rebound

than other areas of the economy.

This rebound was losing momentum in the last quarter of

2020, but not before overall construction activity was

nearly back to pre-pandemic levels. Repair and

maintenance activity, both for housing and non-housing,

an important driver for hardwood demand, was actually

slightly higher than before the pandemic (Chart 3).

IHS Markit Purchasing Managers Index data for UK

construction in December was also positive showing that

the rebound in UK construction activity continued during

the month. According to IHS Markit, new order levels for

UK construction increased for the seventh successive

month.

But according to IHS Markit, the combination of the

pandemic and Brexit meant that supply chains to the UK

construction sector were ¡°groaning at the seams and

delivery times increased to the most dramatic extent for

six months. Low availability for finished products and raw

materials as a result of port disruptions added to builders¡¯

woes as suppliers named their price for goods in acutely

short supply and input price inflation increased to its

highest level since April 2019¡±.

Reports from UK trade associations and business groups

highlight the development of a short supply situation for

building products in the UK driven by a combination of

strong demand and COVID and Brexit related supply

problems. According to the Builders Merchants Federation

(BMF), which represents 760 merchant and suppliers

companies in Britain, high demand, escalating prices for

shipping and delays at some British ports were all having a

¡°major impact¡± on the supply chain.

John Newcomb, chief executive of BMF, said: ¡°Merchants

have seen an exceptional demand for building materials

since the first lockdown.

In November, we saw an average growth of 9 per cent

across our membership compared to the same time last

year.

Looking at December¡¯s figures, we are predicting that

growth could be double digits, and that¡¯s unprecedented.¡±

More specifically on timber, it was noted that ¡°prices in

the UK have risen by an average of 20%¡±.

Housebuilders are racing to complete thousands of homes

ahead of deadlines for the UK government¡¯s Help to Buy

scheme and stamp duty holiday in February and March,

two measures introduced in 2020 to support the economy

during the pandemic. Some of Britain¡¯s biggest builders

including Persimmon and Taylor Wimpey have reported

record order books for the year ahead, as buyer demand

shows no sign of abating.

A spokesman for the Home Builders Federation, which

represents UK housebuilders, said: ¡°Demand remains

strong and whilst builders are committed to completing

homes and increasing supply some constraints have

emerged. Shortages of certain products are being

experienced, alongside Covid-related delays but it is

hoped these will be short term.¡±

The BMF said there has been a surge in costs of building

products shipped in containers from the Far East, which

was already a concern at the end of last year. Mr

Newcomb said: ¡°We continue to see issues with the

availability of products imported in containers, mainly

from the Far East¡±.

Container freight rates from Asia to the UK increased

almost fourfold between November and the end of January

to reach US$10,000 for a 40ft unit for the first time, amid

a global rebound in demand for consumer goods and

materials, ships mothballed with their containers and crew

and congestion across UK ports, where many empty

containers have been left stranded making carriers

particularly reluctant to take bookings for the UK .

The global rebound in shipping demand has been

compounded by Britain¡¯s hurry to stock up on materials

and goods before the Christmas season and the severing of

ties with the EU. This left many shipping containers

stranded by warehouses and on the quayside of ports

across the UK and Europe, after the influx of freight at the

end of last year.

Brexit deal does little to reduce UK costs of trading

with the EU

The Brexit transitional period came to an end on 31

December when the UK left the EU single market.

Contrary to expectations of a ¡®no-deal¡¯ - heightened earlier

in December owing to continuing differences on the ¡°level

playing field¡± for competition, fisheries, and dispute

resolution - an ¡°EU-UK Trade and Co-operation

Agreement¡± was eventually signed on 24 December. This

combines a Free Trade Agreement with an overarching

governance framework.

The signing of the deal means that the worst consequences

of a ¡°no-deal¡± scenario have been avoided, notably that

there will be no tariffs imposed on bilateral trade between

the EU and UK and there is an agreed governance

structure for refining the details of future trade relations in

specific sectors and for arbitration in the event of disputes.

However, it does not alter the fact that the UK has left the

single market and the days of ¡°frictionless¡± trade between

the UK and EU are over.

What this means in practice is now becoming apparent.

The deal is notably thin, not covering the 80% of the UK

economy accounted for by services and, while providing

for zero-tariff trade, it does not exempt UK companies

from the red tape associated with a customs border,

including the need to handle customs declarations for

imports and exports.

In the first few weeks of January, hundreds of trucks a day

are being fined or turned away at cross-channel ports

because they do not have the right paperwork, according

to UK border officials in their reports to UK government.

At the worst point during January, one in five lorries

bound for the EU from the UK was turned back from the

UK border.

This is having a severe knock-on effect. Many companies

on both sides of the border have stopped exporting to

avoid getting caught by new customs regulations and

because of significantly higher transaction costs. At the

end of January, the UK Road Haulage Association (RHA)

said that freight exports to the Continent are still

significantly down on expected levels nearly a month after

the end of the transition period.

The RHA also warned that European hauliers, who make

the bulk of the deliveries into the UK, were starting to

reject UK-bound shipments. In addition to the delays and

extra paperwork, these trips are now much less profitable

because of a 40% decline in UK goods being sent to the

EU since Brexit and many lorries returning empty.

According to the RHA, new requirements for COVID tests

are also very unpopular and having an effect on the

number of hauliers prepared to make the trip.

The worst predictions for chaos and massive tailbacks at

cross-channel ports, leading to shortages in UK supplies of

essential goods such as foods and pharmaceuticals, were

avoided in January as companies had stockpiled goods in

anticipation of a hard Brexit. However there is now rising

concern that the logistical problems in UK trade with the

EU will worsen as stockpiles have been depleted and

cross-Channel trade is due to pick up in February and

March.

Considering the longer-term implications, the UK tax

office (HM Revenue & Customs - HMRC), stated in

evidence presented this month to the UK parliamentary

committee on Brexit impacts, that British businesses will

spend GBP7.5 billion a year handling customs

declarations for trade with the EU ¡ª as much as they

would have done under a no-deal Brexit.

Jim Harra, chief executive of HMRC told MPs that the

number of customs forms needed to trade with the EU

under the Brexit deal ¡°is not materially different from a

no-deal situation¡±.

Mr Harra said that revenue estimates from October 2019,

which found that the cost of no-deal to UK and EU

business would be GBP15 billion a year, still held true

under the deal, with half the bill landing on each side.

HMRC¡¯s impact assessment said that British businesses

would need to handle 215 million more import and export

declarations a year.

The complexity of new ¡°rules of origin¡± has proved highly

disruptive for many UK businesses, particularly those that

use the UK as a distribution hub for the rest of the EU.

The trade agreement only allows for duty and quota free

trade between the UK and EU if exports meet stringent

content requirements. Manufacturers must use a specific

and high proportion of ingredients or parts made in the UK

or the EU, the actual percentage varying depending on the

product group.

This means that manufacturers exporting to the EU from

the UK, and vice versa, must now be able to prove where

all the parts came from. Manufacturers faced with similar

free trade deals will often choose to accept the cost of the

tariff to avoid the cost of all the paperwork.

UK trade relations after Brexit

Having achieved Brexit, the question now arises, what

exactly does the UK government want to do with it? Given

the additional costs and obstacles to trade with the

country¡¯s nearest neighbours and largest overseas

customers, which are self-evident, the UK now needs to

find some benefits.

For the past 45 years, Britain¡¯s economic model has been

clear: to make itself the most attractive destination for

investment by firms looking for a hub for their European

operations. As businesses are discovering, that model can

no longer be sustained now that Britain is outside the EU¡¯s

single market and customs union. The UK government has

yet to clearly articulate what model it believes should take

its place to kickstart the business investment essential to

any sustained recovery.

One objective is apparent: to encourage greater direct UK

trade with a wide range of countries outside the EU. A

key idea behind Brexit was to give the UK greater

freedom to negotiate trade agreements with partners

outside the EU that more directly benefit UK interests.

Certainly, the UK has been busy securing trade

agreements since the Brexit decision. In the last 2 years,

the UK has agreed trade deals covering 65 countries

outside the EU. However, nearly all these just roll-over

existing EU agreements and largely replicate the terms of

trade that the UK previously enjoyed as part of the EU.

An agreement signed with Japan in October was the first

to differ from an existing EU deal, going further in areas

such as e-commerce and financial services, but according

to Dr Minako Morita-Jaeger, International Trade Policy

Consultant and Fellow at the University of Sussex: ¡°while

the Agreement has a certain political significance, its

economic impact is likely to be very small. This is because

it contains very limited improvements relative to the EUJapan

Economic Partnership Agreement (EPA).¡±

The same is true of the UK-Vietnam Free Trade

Agreement (UKVFTA), signed on 29th December, which

also inherits most of the contents of the EU-Vietnam FTA

(EVFTA), with only minor differences in relation to the

UK¡¯s commitments to tariff exemption for a limited range

of Vietnamese agricultural products and differing

commitments from Vietnam to opening the service market

for British businesses.

Potentially more significant, and directly relevant for

tropical wood suppliers, was the announcement in January

by Liz Truss, the UK Trade Secretary, that the UK will

shortly submit a formal request to join the Comprehensive

and Progressive Agreement for Trans-Pacific Partnership

(CPTPP), the free trade area comprising Australia, Brunei,

Canada, Chile, Japan, Malaysia, Mexico, New Zealand,

Peru, Singapore, and Vietnam.

The UK government has taken other steps to integrate with

Asia¡¯s regional blocs following its successful bid to

become a Dialogue Partner of the Association of Southeast

Asian Nations (ASEAN). As a Dialogue Partner, the UK

gains high-level access to ASEAN, alongside enhanced

practical cooperation on various policy issues with the

regional bloc. It also enables the UK to join other

important dialogue partners, including the US, China, and

India.

On the other hand, the UK government¡¯s hopes of striking

an early trade deal with the US ¡ª seen as one of the

biggest prizes of Brexit ¡ª have faded after new warnings

that such a deal would not be a priority for President

Biden¡¯s new administration. While the UK government

claims that much of the work needed to secure a trade deal

with the US has been done already, it has also admitted

that an agreement is unlikely in 2021.

The most difficult areas of a UK-US deal ¡ª including

agriculture and pharmaceuticals ¡ª are still unresolved and

in any case the US is now more likely to prioritise a

possible EU trade deal. The UK¡¯s hope of facilitating

greater trade with the US may now lie in the Biden

administration¡¯s decisions on CPTPP participation.

How can UK businesses become more internationally

competitive?

In addition to trade agreements, the UK government is

consulting business leaders to provide ideas for so-called

¡°regulatory divergence¡±; ways and means by which UK

businesses may be made more internationally competitive

by moving away from the EU¡¯s regulatory regime. But

here again there are no easy options or quick wins.

According to The Times, ¡°the government¡¯s problem is

that businesses aren¡¯t clamouring for Britain to diverge

from EU rules. Rather the opposite¡.no one is demanding

a watering down of employment and environmental

regulations¡±.

On the contrary, they are keen to abide by rules which are

already well embedded into their business operations that

are demanded of their large customers in the EU, and any

move to deregulate now carries the risk that the EU will

retaliate by putting up additional barriers to trade. The

Times concludes ¡°the clamour in many sectors right now

is not for divergence but convergence¡±.

It is still early days and perhaps in time new opportunities

will emerge from Brexit for businesses in the UK as they

adjust to the new trading regime and are, in effect, forced

to increase their global competitiveness as they no longer

have friction-free access to the large EU market.

However, at present, it is hard to see how the new

opportunities will be sufficient to offset the significant

new obstacles imposed on trade with the UK¡¯s nearest

neighbours and largest export markets. In practice, the

pressure from UK businesses is likely to be on retaining

high levels of access to the EU market, even at the price of

foregoing divergence with EU rules.

Implications of Brexit on demand for tropical wood in

the UK

The long term effects of Brexit on UK imports of tropical

wood products are still far from certain. At present, even

the short term effects are obscured by the unprecedented

disruption to supply chains, shipping operations and

markets during the COVID pandemic.

However, it seems likely that, despite the agreement of a

trade and co-operation agreement with the EU, the relative

competitiveness of EU-based suppliers of wood and wood

furniture products that previously benefitted from

completely frictionless trade will be reduced in the UK

market. Tropical suppliers will be competing on a more

level playing field in this market.

Furthermore, the early signs of serious disruption in the

trade between UK distributors and large hardwood traders

in continental Europe, notably in Belgium and the

Netherlands, has some potential to encourage (once again

more direct imports of tropical woods into the UK.

On the other hand, the ability of UK importers themselves

to distribute tropical wood products across the EU is now

much diminished. Furthermore, the potential gains due to

tropical suppliers increased competitiveness in the UK

may well be insufficient to offset the longer term drag on

economic growth now that the UK has left the single

market.

The UK government's own 2018 analysis of the impacts of

various different UK-EU trading relations following

Brexit suggests that in the scenario closest to the actual

outcome - a free trade agreement with tariffs on goods and

non-tariff barriers equal to those in an average trade deal

with the EU - the UK economy will be between 4.9% and

6.7% smaller fifteen years from now compared to

continued EU membership.

Other implications of Brexit for tropical wood supplies in

the UK were discussed in the December market report

(ITTO TTMR Volume 24 Number 23, 1-31 December

2020 pages 27-30). The conclusions drawn there with

respect to introduction of the UK¡¯s new ¡°Global Tariff¡±

regime, the due diligence requirements of UKTR

compared to EUTR, construction product standards, and

phytosanitary requirements, are unaltered by the details of

the EU-UK deal signed on 24 December.

UK tropical wood furniture imports down 23% to

November last year

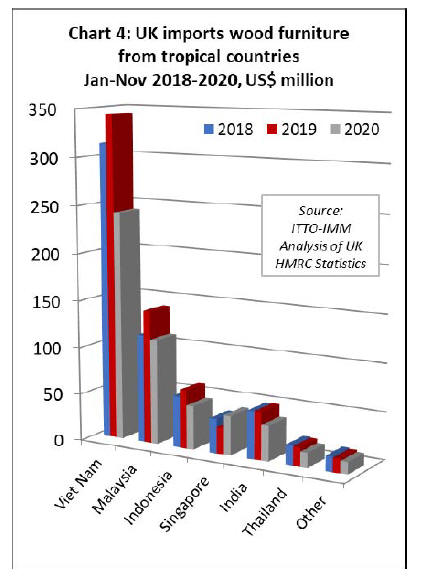

Overall UK imports of tropical wood furniture products in

the eleven months to end November last year were

USD506 million, 23% less than the same period in 2019.

Imports gained momentum during October, rising to

USD57.7 million compared to USD55.3 million in

September, but then slowed a little to USD56.3 million in

November.

Comparing the first eleven months of 2020 with the same

period last year, UK imports of wood furniture declined

sharply from all the leading tropical supply countries

(Chart 4).

Imports from Vietnam were down 30% to USD242

million, imports from Malaysia fell 21% to USD111

million, imports from Indonesia declined 25% to USD46

million, imports from India fell 26% to USD37 million

and imports from Thailand were down 22% to USD16

million. In contrast, there was a 50% rise in imports from

Singapore, to USD41 million.

The current quantity and direction of international trade in

furniture is heavily influenced by freight issues. In an

article in the Guardian newspaper on 27 January, Vincent

Clerc, chief commercial officer for Maersk, the world¡¯s

biggest shipping company, is quoted as saying there are

¡°simply not enough containers in the world to cope with

the current demand¡±.

He said that recent lockdowns in the UK and across

Europe may even spur further online purchases of

consumer goods including furniture for ¡°at least for some

weeks ¡ It is really crazy how much we are moving at the

moment, huge amounts,¡± he said.

The Guardian refers to one factor that might be driving

recent growth in UK furniture imports from Singapore,

noting that ¡°Giant container carriers left off the coast of

Singapore during the most stringent coronavirus measures

last spring have already re-entered the shipping market to

help ship containers to Europe¡±.

Pace of UK tropical wood products imports slows in

November

UK imports of all tropical wood products in Chapter 44 of

the Harmonised System (HS) of product codes in the

month of October were USD42.3 million, the same level

as in September, but declined to USD38.6 million in

November.

Comparing the first eleven months of 2020 with the same

period in 2019, total UK import value of tropical wood

products was, at USD386 million, 23% less than the same

period in 2019.

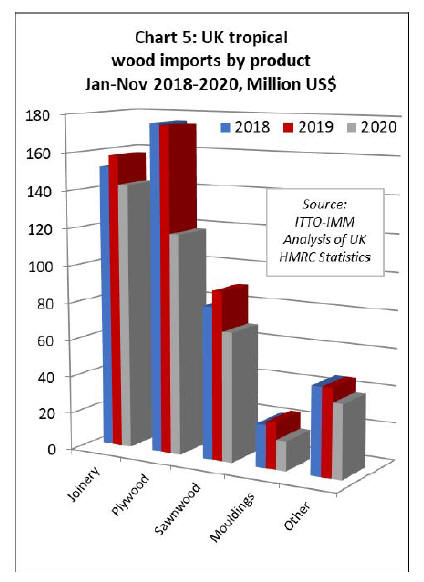

Import value of joinery products was down 10% at

USD143 million, tropical plywood was down 32% at

USD118 million, tropical sawnwood fell 23% to USD69

million, and mouldings/decking declined 36% to USD16

million (Chart 5 above).

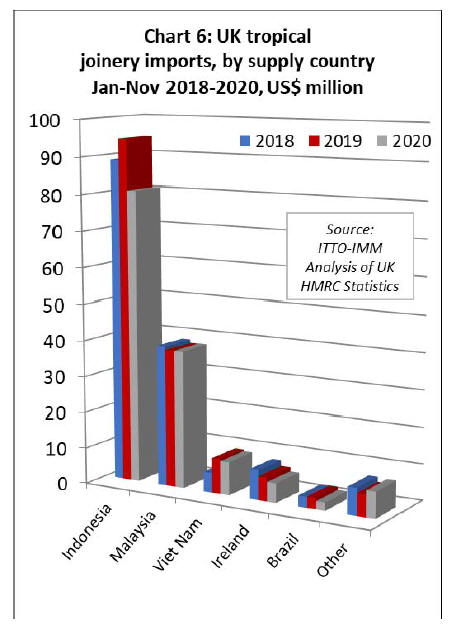

After making gains in 2019, UK imports of tropical

joinery products from Indonesia, mainly consisting of

doors, fell 15% to USD81 million in the first eleven

months of last year (Chart 6). UK imports of wooden

doors from Indonesia made up ground between September

and November after very low imports between June and

August.

After a strong start to the year, UK imports of joinery

products from Malaysia and Vietnam (mainly laminated

products for kitchen and window applications) stalled

almost completely in May before recovering slowly in the

summer months and gaining momentum between

September and November.

Total joinery imports in the first eleven months of 2020

from Malaysia were USD38.0 million, a slight gain from

USD37.9 million in the same period in 2019. Imports from

Vietnam were USD9.2 million in the first 11 months of

last year, 5% less than the same period in 2019.

UK trade in joinery products manufactured from tropical

hardwoods in neighbouring Ireland fell dramatically in

2020, down 18% to USD5.4 million in the first eleven

months. Imports from Brazil were USD2.3 million, down

27% in the same period.

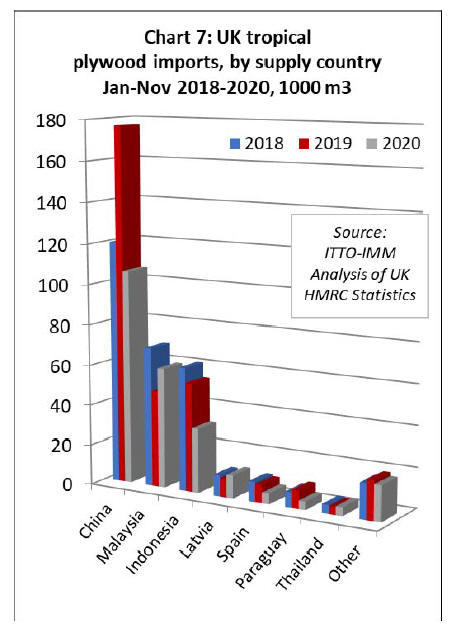

In the first 11 months of 2020, the UK imported 241,000

cu.m of tropical hardwood plywood, 27% less than the

same period in 2019.

Of this volume, around 44% (106,100 cu.m) comprised

tropical hardwood faced plywood from China, 40% less

than the same period in 2019 (Chart 7).

UK imports of plywood from China ground to halt in the

first quarter of last when China went into lockdown. There

were hardly any deliveries from February through to early

April and UK importers were forced to live off

inventories. However imports picked up during the

summer months, rising into the autumn with the arrival of

significant volumes under delayed contracts.

Likely due to supply problems in China, UK imports of

plywood from Malaysia, which were in long term decline

before last year, recovered some ground during the

pandemic period. Despite significant slowing in May,

imports from Malaysia were still up 25% at 59,600 cu.m

for the first eleven months of 2020.

In contrast to Malaysian plywood, UK imports of

Indonesian plywood fell 41% to 31,900 cu.m in the first

eleven months of 2020. In addition to supply problems

during the pandemic, Indonesian plywood continues to

face intense competitive pressure from birch plywood

from Russia, Latvia and Finland.

In recent years, the UK has also been importing a growing

volume of tropical hardwood plywood manufactured in

Latvia. UK imports of this commodity from Latvia were

11,500 cu.m in the first 11 months of last year, 25% more

than the same period in 2019. In contrast, UK imports of

tropical hardwood plywood manufactured in Spain fell

40% to 5,400 cu.m in the first 11 months of 2020.

UK tropical sawn hardwood imports increased in the

second half of 2020

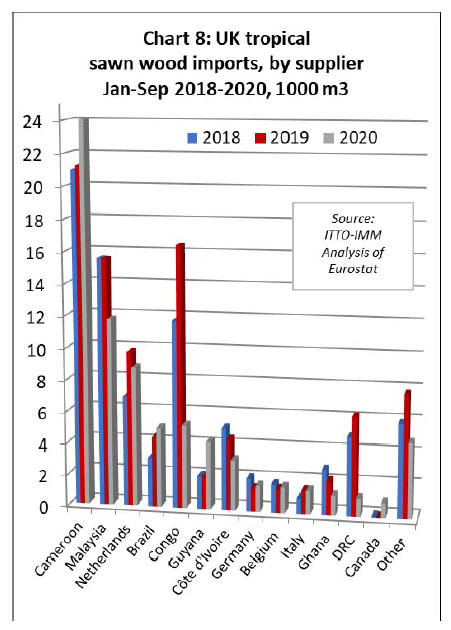

The total quantity of UK imports of tropical sawnwood

was 75,300 cu.m in the first 11 months of 2020, 20% less

than the same period in 2019. While the UK trade in sawn

tropical sawnwood fell sharply in May and June last year,

there was some recovery between July and November.

By the end of November last year, UK imports were up on

the same period in 2019 from Cameroon (+13% to 24,000

cu.m), Brazil (+14% to 5,000 cu.m) and Guyana (+110%

to 4300 cu.m).

However imports from all other supply countries were still

trailing, with declining imports from Malaysia (-24% to

11,700 cu.m), Republic of Congo (-68% to 5,200 cu.m),

Côte d'Ivoire (-28% to 3,200 cu.m), Ghana (-41% to 1,300

cu.m) and DRC (-82% to 1,100 cu.m) (Chart 8).

The UK imported 15,600 cu.m of tropical sawnwood

indirectly from EU countries in the first eleven months of

2020, 17% less than in the same period in 2019. Imports

fell 10% from the Netherlands to 8,800 cu.m and 50%

from Ireland to 400 cu.m.

However, imports increased 14% from Germany to 1,700

cu.m and 9% from Belgium to 1,600 cu.m. Imports from

Italy were stable at 1,500 cu.m.

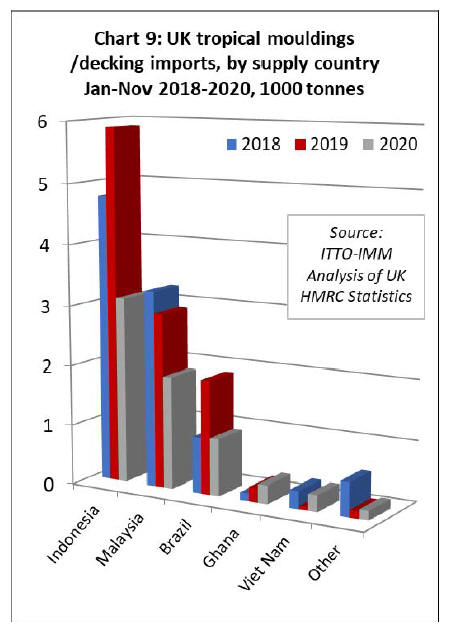

The UK imported 6,700 tonnes of tropical

mouldings/decking in the first 11 months of 2020, 40%

less than the same period in 2019. Imports were down

47% from Indonesia at 3,100 tonnes, 36% from Malaysia

at 1,900 cu.m and 50% from Brazil at 900 cu.m.

There was significant growth from Ghana and Vietnam,

but from a small base, respectively rising 30% to 300 cu.m

and 400% to 300 cu.m. (Chart 9).

|