Japan Wood Products

Prices

Dollar Exchange Rates of

28th June 2011

Japan Yen 80.83

Reports From Japan

Seihoku plywood mills repaired

The Seihoku plywood mills on the east coast of Japan

which were badly damaged by the March 11 tsunami are

under repair.

The Japan Lumber Reports (JLR) is saying that the

Ishinomaki number 3 plant will start producing veneer in

July.

Number 1 and 2 plants will use the veneer from plant

number 3 to manufacture plywood. Output is expected to

be around 250,000 sheets of structural plywood in July.

Seihoku hopes to have all three plants operating by the end

of August.

Prior to the crisis total production from all mills was 1.7

million sheets but the company is saying that by the

autumn this year it should have capacity up to around 60%

of that prior to the March disaster.

The operation of the particleboard and MDF mills will not

be possible before November this year as both factories

suffered extensive damage.

In other news the JLR is reporting that Hokuyo Plywood is

saying that its Miyako plant will be able to begin

operations in July. This plant produces softwood plywood.

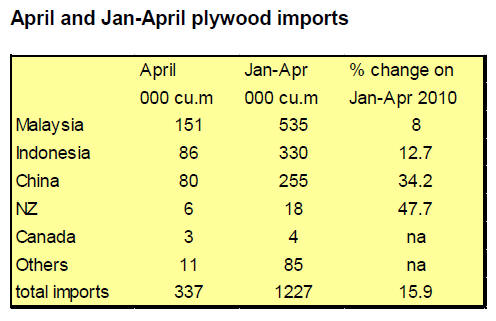

Surge in April plywood supply

The total supply of plywood in the Japanese market in

April was 533,100 cu.m, some 28% more than in April last

year and 19% more than in March this year.

There was a sharp increase in imports and domestic mills

that were unaffected by the earthquake and tsunami

increased production by almost 20%.

April imports amounted to 337,100 cu.m, 12% more than

in April 2010. This was the highest monthly import level

since October 2008 and over 75,000 cu.m more than the

average monthly volume for last year.

Tropical log demand projections

The Japan South Sea Lumber Conference held a regular

meeting to assess the likely demand for tropical timber in

2011.

The forecast demand for logs in 2011 is 529,000 cu.m.,

5.5% less than in 2010. The forecast for plywood demand

is 440,000 cu.m., almost 6% down on the level in 2010

while for sawnwood the forecast is for a demand level of

89,000 cu.m, 3% less than in 2010.

The demand for tropical logs is forecast to be less than last

year because so many plywood mills have been damaged.

Even if the unaffected mills increase production as

expected their consumption will not be sufficient to bring

production up to 2010 levels.

Sarawak log prices levelling out

Weather conditions have been improving in Sarawak

allowing logging operations to get back to normal and log

production is increasing.

As log supply has improved, and as the orders for plywood

are levelling off, log prices seem to have reached their

peak reports the JLR.

Sarawak Meranti regular is selling at US$350-360 per

cu.m FOB, unchanged now for two months. Meranti small

logs are priced at US$320-330 per cu.m and super small

priced at between US$300-310 per cu.m.

In contrast to the situation in Sarawak, the JLR is reporting

that the situation is rather different for log exporters in

Sabah as they have strong order books, because of this log

prices remain firm.

Kapur prices are at US$400 per cu.m FOB (floaters and

sinkers).

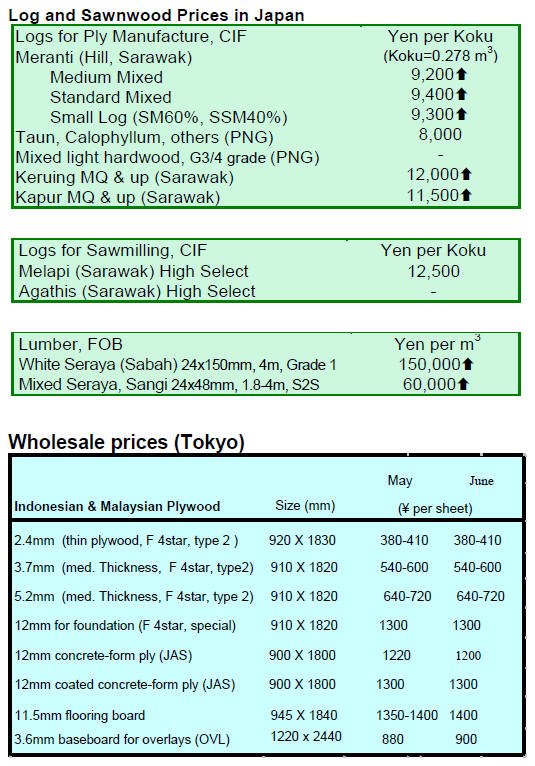

Slow plywood market

Sales of tropical plywood in Japan are slow says the JLR

because a large quantity of plywood arrived this month.

The domestic mills are still struggling to increase

wholesale prices to compensate for the high cost of

imported logs.

Current prices of Sarawak Meranti regular logs in the

Japanese market are Yen 9,300 per koku CIF, Yen 1,000

per koku higher than in December last year.

JLIA gets new chairman

The Japan Lumber Importers Association held its general

meeting in early June and elected Mr. M. Ogawa of Sojitz

Corporation as it new chairman.

The JLR reports that Mr. Ogawa said that the Association

will continue to build a strong relationship with forest

products groups in SE Asia, Russia, N. America and

Europe to establish a steady import of wood products.

The meeting heard that in the year to March 2011 imports

of certified wood accounted for 41% of all imports up 5%

on the previous year.

Samco makes plantation plywood

The Indonesian group Samco has been developing the use

of plantation logs for plywood production. The group

apparently uses plantation Pinus merkusii, the Sumatran

Pine and falcata for cores and Meranti for the face and

back.

The JLR reports that, currently, about 70% of the mill

output is marketed domestically with the balance 30%

being shipped to Japan.

Related News:

|