Japan Wood Products

Prices

Dollar Exchange Rates of

30th Oct 2010

Japan Yen 80.47

Reports From Japan

August plywood imports down from July

According to the Japan Lumber Reports (JLR), plywood consumption in

Japan during August was 506,376 cu.m, up 22% from August 2009, but 5%

less than recorded in July 2010.

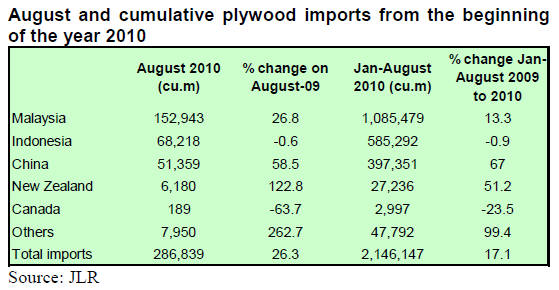

August plywood imports amounted to 286,800 cu.m, an increase of 26% from

August last year, but lower than July 2010 imports which topped 303,000

cu.m. The strong Yen has encouraged importers to increase imports.

However, importers are becoming cautious as the market in Japan remains

subdued and thus, arrivals are expected to decline for the last quarter

of the year. Plywood imports from Malaysia for the first eight months of

the year have been more than expected, says JLR.

Plywood demand picks up for period under review

Due to relatively low inventories and improved demand, imported plywood

prices firmed.

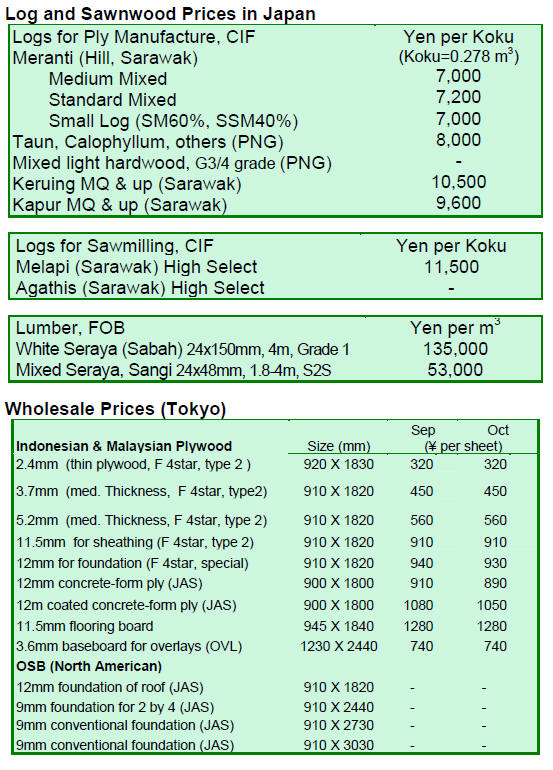

The average market price for imported 3x6 concrete formboard is now Yen

880-890 per sheet delivered. Prices for 3x6 coated concrete formboard are

now at Yen 1,040-1,050 per sheet and for 2x6 at Yen 760-780 per sheet. JLR

reports that the strong Yen is offsetting the FOB price increases in US

dollar, keeping prices relatively steady.

Plywood mills in producer countries reportedly have orders for the next two

months. Currently, mills are procuring logs swiftly to build up log

inventories as the rain season is beginning and thus will have an impact on

log supply.

Kapur log prices climb sharply

Kapur log prices in Sarawak are moving up sharply, reports JLR. FOB prices

reached US$300 per cu.m for kapur regular logs and suppliers in the Tanjung

Manis port have been asking for higher prices. At the Baram port, prices are

slightly lower at US$295-298 per cu.m, up by US$40-45 per cu.m from the

beginning of the year. Kapur log prices in Sabah fetched US$270 per cu.m.

As selangan batu log prices exceeded US$500 per cu.m FOB, India shifted to

import other species like meranti and kapur increasing demand and prices for

these species. Much of the logging in Sabah and Sarawak is now carried out

in remote areas, thereby increasing log transport costs and resulting in

delays. Prolonged poor weather conditions and the strong Malaysian Ringgit

against the US dollar are lifting up the FOB prices, reports JLR.

During the period under review, meranti FOB prices soared to US$230 per cu.m

for regular logs and to US$200 per cu.m for small logs.

Plywood industry groups hold meeting in Kuala Lumpur

A regular meeting between plywood industry groups of Japan, Indonesia and

Malaysia was held at Kuala Lumpur, Malaysia, reports JLR. At previous

meetings, the market situation in Japan and supply situations in producer

countries were the main topics. During this meeting, the main issue

discussed was on increasing the production of plywood using environmentally

friendly raw materials and on evolving markets for these products. Suppliers

also expressed the need to expand markets, rather than depending heavily on

the Japanese market.

Participants agreed on the importance of sustainable production, and in this

regard Indonesia and Malaysia are following the eco-plywood trend led by

Japanese producers and increasing the production of plywood from plantation

and certified wood.

Malaysian and Indonesian producers have begun to use acacia magnum and

falcate for plywood production respectively. Both species are fast growing

plantation species. According to Indonesian and Malaysian representatives,

native natural forest species such as meranti, kapur and keruin are only

sourced from sustainably managed forest units.

The Japanese plywood industry groups reported that despite the fact that

more than 80% of plywood produced in Japan are made of native softwood like

cedar and larch, it is important to have plywood made from environmentally

friendly raw materials from Southeast Asia.

Japanese representatives also pointed out that the Japanese government’s

policy of increasing the use of domestic wood to 50% of the total wood

consumption, does not mean that imported wood will be replaced by domestic

timber. Rather, the policy is set to boost the overall demand for both

domestic and imported wood products.

The meeting reviewed the status of tropical timber supply from Indonesia and

Malaysia to Japan. In Indonesia, there were 130 plywood mills exporting

plywood products in 2006, while in 2009 the number of mills was only 31. The

monthly production is currently around 200,000 cu.m of plywood.

During the first half of 2010, Indonesian exports of plywood totalled 73,000

cu.m. The major markets for the Indonesian plywood were Middle East and

China while 18% of the total export volume was exported to Japan.

Malaysia imposes a log export quota at 40% of the total log production of

around 10 million cu.m per year for exports. In August this year, log

exports from Malaysia amounted to 2,71 million cu.m, up 19.7% compared to

August 2009. Plywood export volume in August was 240,000 cu.m, a 6.9%

increase over the same month in 2009. Out of the total plywood exports from

Malaysia, 47% was exported to Japan.

Forest plantation area in Malaysia is currently more than 200,000 hectares

and the government’s plan is to expand the area up to 1,000,000 hectares by

2020. As a result, the supply of plantation wood to Japan is expected to

grow.

Greater use of eco-materials in flooring

Tostem Corporation announced its strategy “Environmental Commitment 2015” in

July. According to this strategy, Tostem Corporation will shift to

eco-materials in flooring manufacturing in 2011. It also plans actions

towards changing the raw materials used for doors, cabinets and stairs to

eco-materials.

According to JLR, Tostem has begun marketing two eco flooring products:

‘Ecohard 12’ with the base board made of wood chips from waste wood and

‘Harmonious light 12E’ with the base board made of falcate plantation wood.

‘Ecohard 12’ was introduced to the markets in December 2009 while

‘Harmonious light 12E’ in September 2010. Tostem is said to have increased

the use of eco-materials in its production to 70% with these recently

introduced products. The balance is medium and high grade flooring with

plywood face from natural forests, but this will also be replaced by

eco-materials in 2011, with plantation wood being the most likely material.

Daiwa House adopts wood procurement guidelines

Daiwa House Industry Co., Ltd. (Osaka) has adopted wood procurement

guidelines in order to implement its biodiversity action plan. Daiwa House’s

wood consumption totalled 250,000 cu.m in 2009.

According to the guidelines, wood products to be procured must be certified

by recognised schemes. The guidelines also recommend the utilisation of

recycled timber products such as particleboard and wood products.

OSSB for the Japanese market

AD World Co., Ltd. (Tokyo) is marketing OSSB (Oriented Structureal Straw

Board) in the Japanese market for flooring base boards and as alternative to

plywood and furniture materials. OSSB uses straw as raw material which is

normally burnt after harvest of wheat or used to fertilize fields, thereby

generating greenhouse gas emissions. OSSB is said to be a more environmental

option for the use of straws.

In the Japanese market the product is called ‘Harvest Panel OSSB’ and it has

been produced in Shaanxi Province China since November 2009.

Related News:

|