|

Report

from

Europe, the UK

and

Russia

Re-stocking plywood

The market for tropical hardwood plywood in Europe is

now winding down for the Christmas break which is likely

to be extended this year. However there has been some

forward buying in recent weeks as importers have been

filling gaps in stocks in preparation for the New Year.

Although very few people are expecting a dramatic

turnaround in demand during the first half of 2010, there is

mounting concern that temporary supply problems may

arise due to short-falls in landed stocks.

For much of 2009, European importers focused on

winding down stock levels in the face of weak underlying

consumption and uncertain economic conditions. For the

first six months of the year, the large European plywood

importers shifted away from bulk to container shipments

as rates for the latter were extremely low and as importers

were looking increasingly to buy smaller mixed batches.

However since the middle of 2009 freight rates have risen

consistently as shipping lines reacted to the decline in

trade by decommissioning a large number of vessels. Now

much of the remaining capacity is overbooked. A 3-4

week gap between placing of forward orders and shipment

to Europe has opened up making it more difficult for

importers to fulfil short-term obligations. Importers may

therefore be forced to build and carry more stock during

the early part of 2010.

Shifting to combi-products

This year the UK market has shifted increasingly away

from tropical-hardwood- throughout plywood in favour of

products with a pine or poplar core. While bearing a

passing resemblance to tropical hardwood plywood, the

combi-product is much cheaper and 每 being widely

offered from CE2+ certified mills - is generally regarded

as providing adequate performance for a range of fairly

utilitarian tasks in the UK.

Government green procurement policy in the UK has also

tended to favour increased use of combi-product. Until

recently there was particular interest in FSC Mixed

products manufactured in Malaysia from an FSC-certified

New Zealand radiata pine core and an MTCS-certified

tropical hardwood face. However with the recent

endorsement of MTCS by PEFC, more of this product is

expected to be supplied with the PEFC logo.

The first shipment of PEFC-certified Malaysian combiplywood,

of around 10,000 cubic metres, is expected to be

shipped to the UK in January. This is believed to be priced

at around US$400/cu.m CIF UK for 18 mm product,

significantly cheaper than the uncertified tropicalthroughout

plywood.

Manufacturers of alternative plywood products are also

trying to exploit the rising interest in PEFC and FSC

certified product in the UK plywood market. Weyerhauser

has been particularly active marketing ※tropical

replacement panel§.

This is available FSC-certified and manufactured from

Uruguayan plantation-grown eucalyptus. It bears a passing

resemblance to tropical plywood, is supplied by a CE2+

certified mill and prices are very competitive. On the other

hand, according to one major UK importer, the product is

derived from smaller-diameter logs, cannot match the

performance of tropical hardwood plywood and the

volumes available are not yet large.

Drift away from Chinese plywood

The UK plywood market*s dependence on China has

tended to decline this year. One large UK importer notes

that ※three quarters of Chinese manufacturers that were

formerly manufacturing plywood are no longer involved in

the plywood trade 每 most UK importers are now only

dealing with a small number of larger better performing

mills§.

This importer also noted that, due to lack of capital and

credit, many Chinese mills are now asking for a 25%

deposit up-front in order to purchase raw materials. This is

a major disincentive to European importers buying from

China.

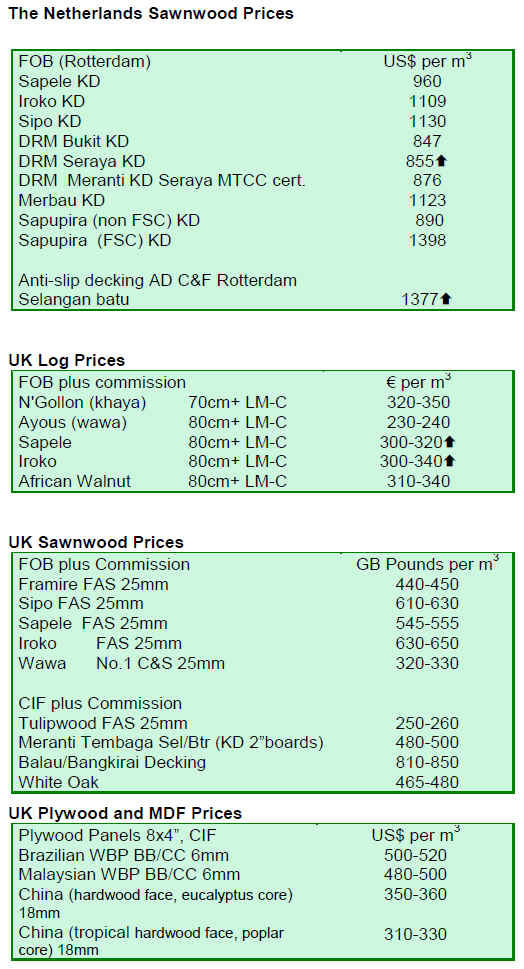

Caution in market for tropical hardwood lumber

European tropical hardwood lumber importers have

maintained a cautious approach to forward orders

throughout the final quarter of the year. This is despite the

combination of a strong euro, the widespread belief that

European stocks are now quite low and signs that FOB

prices for key products in both Africa and Asia are rising

on the back of tight log supplies.

There is still great uncertainty over the likely level of

European tropical hardwood consumption next year. Few

importers are willing to speculate on market conditions 3

to 4 months in the future 每 which is the current lead time

between ordering and delivery for African sawnwood.

Lack of credit and cash-flow continue to be problems for

many importers. As a result forward orders in recent

weeks have concentrated on small mixed batches to fill

gaps in stocks as they emerge.

Although some of the larger European importers engaged

in the tropical hardwood trade report reasonable levels of

trade this year 每 particularly those with a varied stock base

and capable of delivering over a wide distance at short

notice 每 most companies reckon that sales will have

slumped by double-digit percentages in 2009.

Margins have also tightened as intense competition

between importers has put downward pressure on

European wholesale prices at a time when CIF prices have

been rising. There continue to be reports of importers

being forced to sell tropical hardwood lumber at below

replacement price.

Decking orders

At this time of year, importers would normally be placing

significant orders for garden decking products for the

spring season. However orders are well down this year as

the large merchants and retailers have been very reluctant

to indicate their needs for 2010.

Window frame market

The German window frame market is one of the few

bright spots in a generally gloomy picture. This sector is

creating consistent demand for Malaysian and Indonesian

Meranti window scantlings, but relatively high prices for

the Asian hardwoods and limited availability mean that the

actual volume of trade is now low.

|